WHO WE ARE, WHERE WE ARE, AND HOW WE CAN HELP

Plunger-assisted gas lift (PAGL) is a continuous injection and continuous plunger lift operation that is implemented on higher gas and fluid producers. These wells require the addition of injection gas to raise the critical velocity needed to lift both the plunger and the commingled fluid of the well. Producers are able to optimize certain gas-lifted assets with the introduction of a continuous-flow plunger system. By implementing continuous flow plungers at the right time in a well’s life, operators can increase production, maximize estimated ultimate recovery, and optimize gas lift control, including required injection gas.

In this success story, the operator identified a horizontal well candidate located in the DJ Basin, a geologic structured basin in Northern Colorado. The candidate was previously on a gas lift system that struggled to maintain injection due to excessive slugging. David Dahlgren, the Flowco Production Solutions regional production expert recommended the APEX Multi-Well Controller with proprietary advanced well-control functions and the installation of a continuous-flow, ball and sleeve plunger as a solution to the production challenge. The APEX controller has advanced gas lift optimization features built-in including downhole gauge management. For GAPL or PAGL wells, the controllers employ a patented algorithm with cycle-skip technology that optimizes both the gas lift injection and the plunger cycles to get the best performance out of the production system. The controller brings advanced optimization capabilities to either an individual well or a pad of connected assets (up to 16 wells).

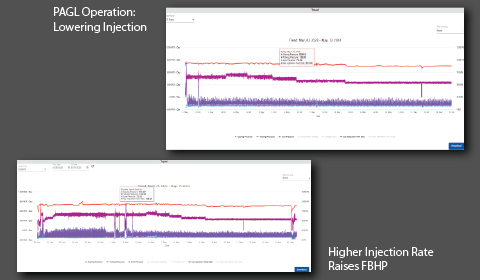

Once the system was upgraded and early line-out operations were implemented, the operator noticed a significantly more efficient flow regime. In addition, the gas lift system was also optimized as injection gas was transferred to the orifice valve. By stabilizing inflow well performance, the overall PAGL lift system stabilized and allowed the well to continuously inject on the orifice valve where previously, primary production was happening on the upper valves. This allowed for a lower flowing bottom hole pressure (FBHP) and reduced well slugging.

Manual plunger lift inputs were attempted, but when optimization functions for gas lift injection and plunger control by the AI-based algorithm from the controller, the results were a 25% decrease in required gas injection and almost a 10% reduction in FBHP.

It’s important to note that optimal control of the well can be automated and remote, whether the points are manually set and assigned by the operator, or the assignments made automatically by the controller. Once operators grow more comfortable with the automated technology features, the tool can deliver production at the optimum rate. Contact your production specialist to discuss how the APEX Multi-Well Controller can address your particular production challenge.

Flowco is committed to providing quality artificial lift solutions as well as turnkey products and services to safely maximize the lifespan and efficiency of oil and gas wells around the globe. For a full list of our artificial lift, production tools, and services, please visit www.flowcosolutions.com. For follow up with one of our lift specialists, please email us at info@flowcosolutions.com.